EDGECAM WORKXPLORE - Native CAD Viewer

EDGECAM WORKXPLORE - Native CAD Viewer

EDGECAM WORKXPLORE là công cụ lí tưởng cho việc hiển thị trực tiếp và đánh giá các file 3D CAD mà không cần các ứng dụng CAD thông thường. WORKXPLORE rất trực quan và dễ sử dụng, giúp người dùng có thể khám phá bất kì loại file 2D/3D CAD nào.

Giải pháp có sẵn một loạt các giao diện CAD như: Catia V5, Catia V4, Unigraphics, Parasolid, Pro/E, SolidWorks, Solid Edge, Cadds, IGES, STEP, Unisurf, STL (binary và ASCII), VRML, đường chạy dao ISO, DXF, DWG, HPGL. Đặc biệt, bạn có tể tải dữ liệu GD&T từ các giao diện CAD có hỗ trợ dung sai hình học.

Phần mềm sẽ lưu dữ liệu native CAD trong một định dạng gọn nhẹ, cho phép người sử dụng tính diện tích bề mặt và khối lượng, đo độ dày và kích thước, các góc..vv mà không cần dữ liệu CAD thông thường. Đặc biệt, định dạng trên có thể dễ dàng được chuyển đến các thành viên khác của dự án qua email.

Find out more

EDGECAM WORKXPLORE has been created for the efficient import and analysis of files of all sizes and types but it is the speed at which it imports large 3D CAD files which is particularly impressive, often taking less than half the time to open a file compared to the original CAD application.

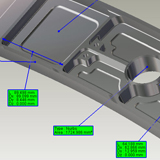

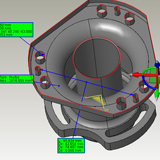

Measurements : EDGECAM WORKXPLORE features a wide range of 2D and 3D measurement functions that are highly accurate due to the high precision B-rep 3D model employed.

Even non-expert CAD users can quickly get to grips with the software’s measurement functions and obtain good results instantly by using the software’s predefined selection modes (points, 2D entities, planes, surfaces, etc).

Measurements can be automatically included as measurement entities and can be anchored to characteristic points of the part. Entity labels automatically pivot to remain visible at all times.

EDGECAM WORKXPLORE’s specialist measurement functions allow expert CAD users to recover point clusters from three-dimensional measuring equipment or machine probes and to quickly check any data revision against the original CAD geometry. The software also allows users to easily generate control point files for transmission to three-dimensional measuring equipment or NC machines.

Annotation : EDGECAM WORKXPLORE offers a wide range of annotation functions. Users can convey their ideas, observations, instructions and change requests easily and quickly.

The need for 2D drawings is minimized as users can directly add dimensional and geometric measurements, annotations and labels to the 3D model.

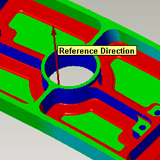

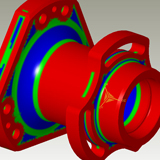

Analyse : EDGECAM WORKXPLORE comes with a full range of specialist analysis tools which can be used to help make quotes, diagnostics, assembly notes or for 3D models production preparation.

EDGECAM WORKXPLORE also offers a range of analysis functions which are usually only available with more costly CAD solutions. As well as being extremely fast and efficient (even on very large models), the software’s functions are very easy to use with results being displayed in color on the 3D model. In a single mouse click, labels are automatically inserted on surfaces displaying accurate values resulting from various calculations.

High performance dynamic sectioning allows users to explore inside a part or an assembly easily and accurately. The dynamic reference controller allows users to control the section plane with the mouse in rotational and panning directions or following a guide curve. The cross section can be made visible on the 3D model or as an isolated entity and can be extracted and exported via the DXF, DWG, etc interfaces.

Curvature radius and plane face analysis is a valuable tool for users enabling fast cost and production time evaluation. The coloring of elements to be analyzed is automatic and users can insert measurement labels containing precize values of the elements selected.

Generation of the bounding box of a part or a set of parts is instantaneous and provides information on the dimensions, volume and weight of the selected elements. This can also be used to determine the optimal stock model required for manufacturing.

Precize measurement information is available both on objects and surfaces and enables rapid calculation of volumes and areas. Complementary information such as the object name, encumbrance, number of faces, etc. is also available.

The calculation and display of drafts and undercuts are extremely quick, even on very big parts. EDGECAM WORKXPLORE automatically colors drafts and undercuts according to the mold stripping axis. Precize draft angle values are displayed dynamically as the mouse is dragged over the surfaces and can be inserted by default in the 3D model.

Automatic 3D part comparison allows real time 3D graphic display of the differences between two versions. Modifications are clearly identified by different colors to distinguish between material added and material removed.

Amimation : EDGECAM WORKXPLORE includes a fully functional animation kernel allowing users to generate exploded views or animated assembly movements. Setting up animations is achieved by simply initiating basic movements such as translation, rotation or following a guide curve.

Interference Detection : Dynamic collision analysis functions can be used during animations to carry out real time control of mechanism interoperability or process control.

Users can also generate short videos directly from the animation menu that can then be shown to customers or other project members.